COMPONENTS OF PEB STRUCTURE

Pre-Engineered buildings or PEBs structure are made up of various components that give them their unique properties and make them sturdy and durable. Pre-Engineered Buildings are known for their flexible design, high structural strength and ease of construction. But all this is made possible due to the various components that go into building a PEB. Just like any assembled structure, a PEB consists of components that can be categorized into 3 main types and a few accessories.

A PEBs Structure (Pre-Engineered buildings) is made of:

- Primary Components

- Secondary Components

- Roofing or Cladding

- Other Accessories

1 – Primary Components

The Primary components include 3 main parts: Main Frame, Columns and Rafters.

Main Frame:

The main frame is the basic structure of the building which is made of rigid steel. It is built using tapered columns and rafters, sometimes also referred to as built-up members. There are spliced plates welded to the end of these tapered sections. The splice plates of connecting sections are bolted and the frame is erected.

Columns:

The columns are load-bearing members that support the roof and floors of the building. The beams transfer loads from the columns to other structural members. Purlins, girts, and bracings are secondary members that provide additional support.

Columns are used to transfer the vertical load to the foundations. These are generally made up of I sections which give benefits in terms of strength while being economical to produce.

Rafters:

Rafters are sloped structural members or beams that extend from the ridge or up-to-the wall-plate. They are designed to support the roof deck and other loads associated with it.

2 – Secondary Components:

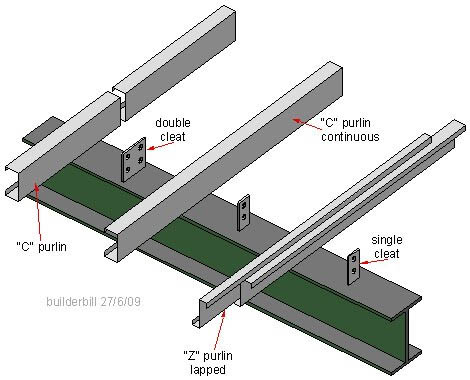

Purlins are steel elements which are used as support structures in pre-engineered buildings, mainly below the roofs. Purlins provide extra roof support, creating a horizontal diaphragm that provides support to the weight of the roof and deck.

Purlins, Bracings, Tie rods, Angle bracings, High Tensile Bolts and washers etc. are classified as secondary components that are used in a PEB. These parts are used to support walls and roof panels. In addition to that, the secondary members also help the building withstand the longitudinal loads that the building may see during earthquakes and heavy winds. Purlins are mostly unique cold roll-formed sections used to fix roof and side claddings. They are available in different variations such as Z, C and Sigma purlins which are denoted by their cross-section.

3 – Roofing or Cladding

Roofing Sheets, as their name suggests, provide protection to the building interior from the environment. They can be designed to either block sunlight or allow partial sunlight to illuminate the interiors, depending on the requirement. A Standard supply of material for Roof Sheets is 0.47 mm Bare Galvalume and for wall Claddings it is 0.50mm Color coated Galvalume.

4 – Other Accessories:

Several accessories are available for Pre-Engineered Buildings or PEBs structure that can greatly increase the functionality of the building. Depending on the type of application, the accessories may be selected. Some of the many available accessories used in PEBs are

- Windows

- Turbo Ventilators

- Louvres

- Sliding Doors

- Roll-Up Shutters

- Skylight Sheets

- Ventilators

- Downspouts etc.

Other Components:

#1-Anchor Bolts:

Anchor bolts are used at each steel column and at each door jamb. An anchor bolt has a threaded end that is used to bolt the external load with a nut and washer. The embedded end of the anchor bolt has either a hook on the end or a welded nut and washer.

#2-Crane Beams:

In PEB, when a crane system is required, crane runway beams are required to support the crane system. Complete system information of Crane is required to design and estimate the same. Usually PEB companies supply Crane Girders because installing and aligning it throughout the length of a building, requires expertise.

#3-Mezzanine Beams:

Mezzanine is related to loading requirements for office and storage. Mezzanine floors consist of steel decks and are supported by joists framed to the mezzanine beams. Main mezzanine beams normally run across the width of the industrial building.

#3-Mezzanine Columns:

A mezzanine floor system for pre-engineered buildings (PEB) is a valuable addition that can significantly enhance the functionality and versatility of such structures. Mezzanine floors are intermediate floors installed between the main ground floor and the roof, providing additional space for various purposes.

#4-Canopy:

Canopies are narrow roof systems that provide various functions, such as a shade to block direct sunlight on the building walls, an extended cover to protect the buildings against the rain, and a cover at entrances of the buildings or adjacent to the walls for car parking.

#5-Purlins:

Purlins are installed parallel to the building eave and are supported by rafters or walls. The raw material used to fabricate purlins are cold formed steel. It can span a length of up to 30 feet or longer. The length and width depends on the dimensions of the primary frame of the building, its usage and engineering design. Added stiffness can be given to purlins to prevent loss of structural strength, as required. Purlins are therefore an important part of the roof structure.

In pre-engineered buildings, steel purlins are widely used. They are lightweight, durable structures that are built to precision, having consistency in dimensions. Purlins expand and contract in summer and winter respectively.